Within the context of Industry 4.0, human-robot collaboration plays a crucial role; it potentially increases the process efficiency while improving human operator working conditions from both an ergonomic and a self-satisfaction point of view. To face this challenge Fondazione Cariverona supported IAS-Lab, BNP Srl, and Allmec Srl in the development and growth of a project called CURAMI in 2020.

CURAMI is a two-year project that aims to implement an intelligent robotic framework able to manage the warehouse and feed the assembly workstations in a semi-autonomous way. CURAMI also assists workers during the assembly and assesses their postures in real-time through an ergonomic tool able to detect potentially dangerous movements and give adequate feedback. The benefits are manifold: the framework reduces human operators’ fatigue, improves their comfort, and minimizes injury risk.

CURAMI is composed of five main modules:

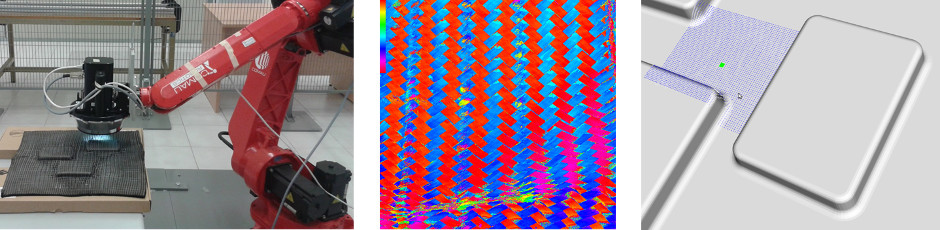

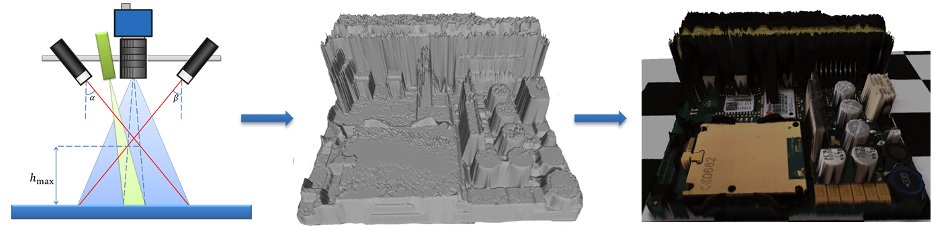

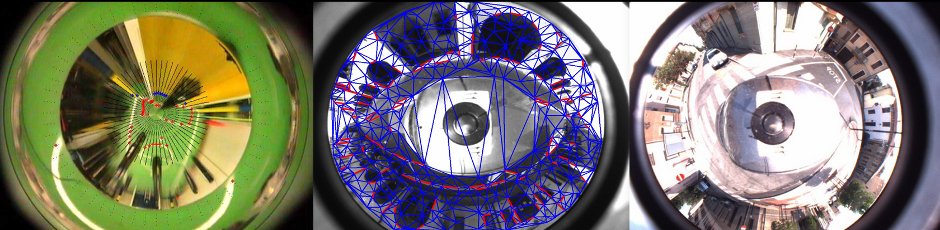

- VISION: A multi-camera system tracks human motions and recognizes assembly components;

- TASK AND MOTION PLANNING: A Task Scheduling routine efficiently supplies assembly workstations while assisting human operators. A collision-free robot Motion Planning module ensures worker safety;

- ERGONOMICS: The worker is provided with a fully adjustable ergonomically designed assembly workstation. Frome perceived data, real-time estimation of the operator upper-body kinematics is performed, principal ergonomic indicators are computed, and exploited to correct postures;

- DIGITAL ASSISTANCE: A digital assistance module supports workers in performing the correct assembly sequence while providing them with improvement tips on their posture;

- KNOWLEDGE BASE: To increase framework efficiency and reduce the overall computational cost, one Knowledge Base stores gained experience and environmental data (e.g., components features, processing and assembly sequences, robot and human capabilities, preferences).