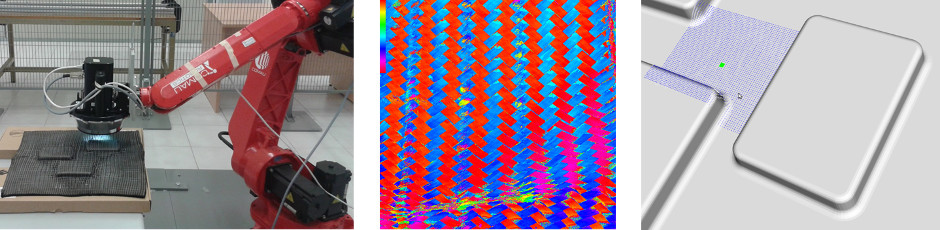

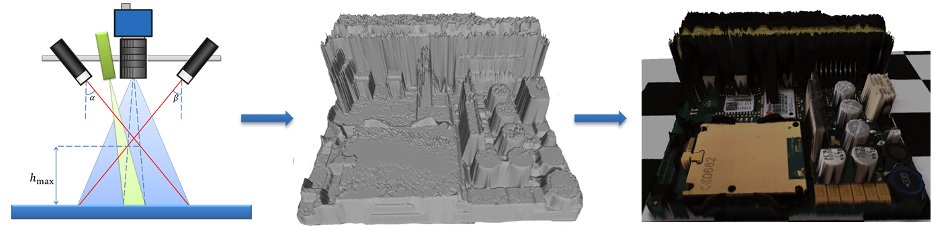

Crack detection in parts of complex geometry is often done manually using magnetic particle inspection. The Thermobot project combines robotics and thermography to replace this decades-old method. Using the inspection of a whole crankshaft as an example a prototype system will be developed that can inspect complex parts, mainly targeting at the automotive industry but also at aerospace applications.

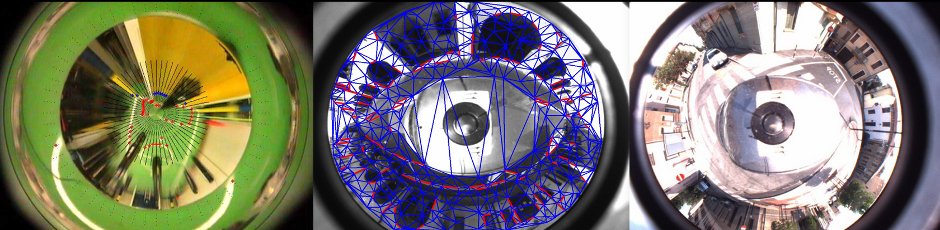

The IAS-LAb is involved in the research and development of algorithms for automatic detection of cracks in metal parts and material intrusions in carbon fiber parts. Such algorithms are able to deal with the different orientations under which a part can be seen, and distinguish between artifacts and real defects.

More information can be found in the Thermobot web page.