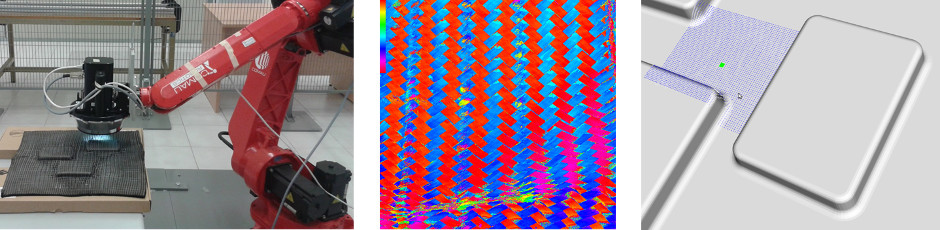

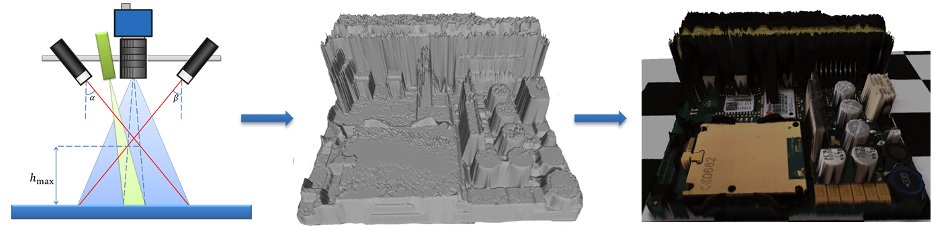

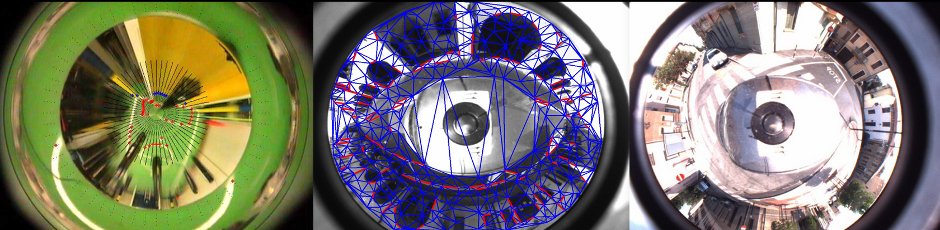

The objective of SPIRIT is to take the step from programming of robotic inspection tasks to configuring such tasks. This includes inspection tasks that use image-based sensors and require continuous motion to fully scan a part’s surface.

The project aims at:

• creating fully automatic offline path planning methods that ensure collision-free full coverage of the areas to be inspected on the part also for complex inspection processes. Instability is the maIn cause of falls for the elderly people, which increases the risk of fractures and therefore disability, with high health and social costs. Fall prevention is one of the targets of social and health policies for the promotion of active aging. The SoftAct project aims to meet this need by developing an innovative neuromuscular controller integrated in a "soft exoskeleton" (exosuit: soft wearable robot) for the lower limb, that can detect the loss of stability during walking or standing by the integration of biomechanical, cerebral and muscular signals. This information will activate compensation systems integrated in the soft exoskeleton to prevent possible fall, with an integrated feedback-feedforward system. The project will see the collaboration of two research groups: the Harvard University, with its experience in gait and muscle signal analysis (EMG), that created the prototype of the exosuit, and the University of Padua, with its strong know-how in the field of brain signal analysis (EEG) and intelligent software for robotics.

• developing reactive inline path planning that is able to automatically adjust to small changes in the environment, such as a different part shape or obstacles.

• a seamless mapping of image sensor data to a 3D model of the part.

• generating operational data of inspection robots in industrial environments. This will include data related to accuracy, cycle times and performance indicators of the integrated system.

The expected impact is:

• Reducing the engineering costs for setting up a robotic inspection task by 80%

• Creating a software framework that allows the shift from project-based, ad-hoc solutions to a product-based approach.

• Reducing the barrier when introducing automatic inspection systems by aiming at a return of investment of less than 2-3 years.

• Realizing a potential of several hundred additional robotic installations per year.

• Helping SMEs to reach out to worldwide markets by providing a proven framework for inspection robots.

The SPIRIT project had its first meeting in Steyr 27-28 February. The general meeting will be 24-26 July at the University of Padova.